TÜV Hessen has certified that Stadtwerke Gießen's TREA II is operating safely. The experts came to this conclusion after extensive tests that took place recently.

Nothing stands in the way of the permanent regular operation of TREA II - at least not from a safety point of view. This was certified by the four-strong team of inspectors from TÜV Hessen at Stadtwerke Gießen (SWG) at the end of the extensive checks carried out in the week from 7 to 11 September 2020. The task was to approve the so-called safety matrix.

Operation without a plant operator

The safety matrix and its acceptance by expert inspectors are due to the fact that the system will usually operate without personnel. Consequently, the system must be able to handle all conceivable critical situations itself. "Basically, it's always about preventing damage to the system and, above all, averting danger," explains Jens Hanig, who is responsible for the project at SWG. And this is exactly what the TREA II is able to do thanks to its numerous safety mechanisms.

Consequently, the inspectors test whether the plant reacts as intended during acceptance. To do this, they simulate faults of all kinds, i.e. put the system into various critical states. In the case of TREA II, the matrix comprised 44 different scenarios. "The TREA II passed all the tests with flying colours," says Jens Hanig happily. Particularly worth mentioning: instead of the originally scheduled five days, the TÜV inspectors only needed three to make their final, positive judgement. This indicates that the TREA's safety technology works exceptionally well.

Worst case first

The worst conceivable scenario for TREA II would be a complete power failure. The system can even cope with this - as the test has shown. Battery-backed computers and intelligent control technology ensure that emergency power generators kick in within seconds and keep all critical components running - such as important fans. At the same time, the TREA shuts down in a controlled manner.

Another problem could arise if the pressure in the boiler rises to significantly excessive levels. To prevent damage, the TREA stops the supply of waste to the grate in such a case and reduces the air required for combustion. "This lowers the temperature in the combustion chamber and consequently the pressure in the boiler," explains Jens Hanig. However, the combustion temperature could also be too low under certain circumstances. For example, if the waste is more moist than planned or its composition is not suitable - for whatever reason. "If this happens, the system first reacts with more combustion air. If this is not sufficient, no more fuel reaches the grate and the fire goes out," Jens Hanig continues. Such a shutdown serves to protect the environment. After all, a combustion temperature that is too low would have a negative impact on the composition of the exhaust gas.

Still in regular operation in 2020

The acceptance of the safety matrix was a key milestone on the way to the operating licence for TREA II from the regional president. In addition to some minor documentation, only the so-called declaration of conformity for fire protection is still pending. "I am convinced that we will be able to complete everything on schedule and transfer the plant from trial to regular operation by the end of 2020," announces Jens Hanig.

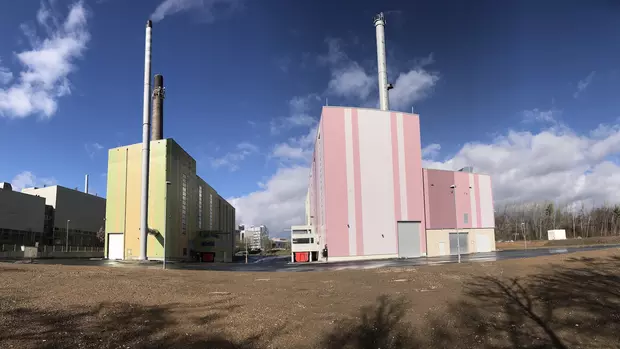

When the time comes, Giessen will have a plant that is probably unique in the world, generating heat and electricity from processed waste in a highly efficient and CO2-neutral way. It is precisely this production of electrical energy that distinguishes TREA II from TREA I, which continues to operate excellently. This is why the second TREA also has two additional natural gas-fuelled combined heat and power plants. Only these make it possible to generate electricity economically. In this respect, the TREA II is a logical further development of the first generation. Much more complex, but even more efficient and also much easier to control.