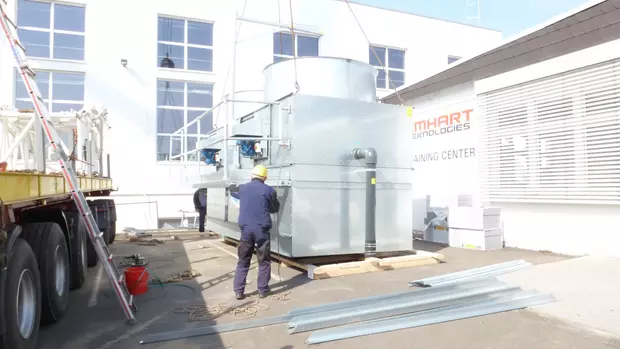

Tucker GmbH recently installed a highly efficient, climate-friendly cooling and heating supply system at its plant in Giessen. Stadtwerke Gießen will take over the operation of the newly installed systems in future.

Ecological aspects are becoming increasingly important in many industrial companies. The example of Tucker GmbH, a specialist in fastening technology from Giessen, proves that economic interests do not have to take a back seat. Since the beginning of this year, the company has completely converted its heat supply to district heating. The cooling required in the new production hall is provided by an absorption chiller. This utilises thermal energy instead of electrical energy to get the cooling circuit going. "We were able to draw on the experience of Stadtwerke Gießen (SWG). They redesigned and built the heating and cooling generation system for our company according to our specifications and will take over its operation in future," explains Maintenance Manager Detlef Pakleppa at Tucker GmbH. As a contractor, the Giessen-based company will only pay for the cooling produced or the heat purchased and will also save investment costs in the six-figure range.

Advantage of the district heating network

The new system works in two different ways and consists of an absorption chiller with an output of 500 kilowatts (kW) and an electric compression chiller with an output of around 200 kW. "We know from our own experience how efficiently heat can be used for cooling. We have been using this principle at Sparkasse Giessen's main branch for several years," explains SWG project manager Pawel Keppen, adding: "A principle for which Giessen offers ideal conditions thanks to its excellent heating network." Tucker GmbH also has a corresponding connection to the SWG district heating pipeline - and it will not only draw energy from this connection, but also feed it into the grid in future.

The compressors used to generate the compressed air produce 200,000 kilowatt hours of thermal energy as waste heat - enough to supply the Heyerweg sub-grid.

Pawel Keppen is certain: "Climate friendliness and cost-effectiveness were priorities during the design phase - and we have managed to optimise the system with regard to both requirements."